Unknown Facts About Uv Filtration

Table of ContentsUv Filtration for DummiesUv Filtration Fundamentals ExplainedThe 3-Minute Rule for Uv FiltrationFacts About Uv Filtration Revealed

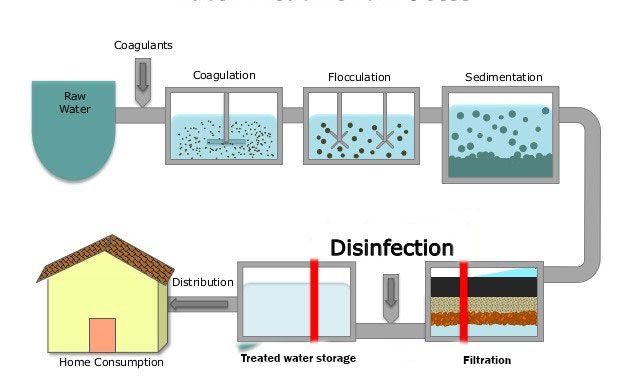

Removal of taste and also smell compounds from the water.: Softens the water.: Filtering to get rid of tiny particles and sanitation to kill infections and also microorganisms, and make certain an unsuitable setting for virus as well as bacteria development throughout the distribution system.

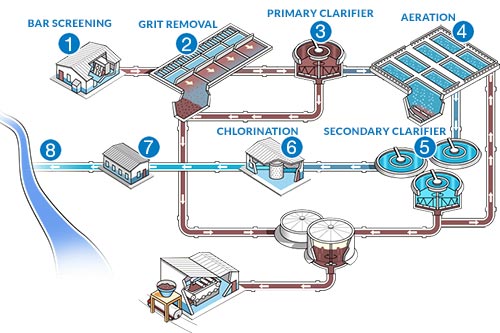

8 Stages of the Wastewater Refine Stage One Bar Screening Elimination of large things from the influent to avoid damages to the facility's pumps, shutoffs and various other devices. The process of treating as well as reclaiming water from wastewater (any type of water that has actually been utilized in houses, such as flushing bathrooms, cleaning dishes, or bathing, and also some water from commercial usage and storm sewage systems) starts with the assumption that after it is treated it will certainly be tidy enough to reenter the atmosphere.

The Basic Principles Of Uv Filtration

According to the EPA, The Clean Water Act (CWA) develops the fundamental framework for controling discharges of contaminants right into the waters of the United States as well as managing quality standards for surface waters. Under the CWA, EPA sets wastewater requirements for sector. The EPA has likewise created national water quality standards referrals for contaminants in surface waters.

Associated White Documents Select Products Phase Two Testing Removal of grit by moving the influent over/through a grit chamber. Great grit that discovers its means right into the influent demands to be gotten rid of to protect against the damage of pumps and devices downstream (or impact water circulation). Too small to be screened out, this grit needs to be eliminated from the grit chamber.

Stage 4 Aeration Air is pumped right into the aeration tank/basin to encourage conversion of visit this page NH3 to NO3 and offer oxygen for germs to continue to multiply and also grow. When converted to NO3, the germs remove/strip oxygen particles from the nitrate molecules as well as the nitrogen (N) is emitted as N2 (nitrogen gas) - uv filtration.

This starts in the aeration container. The main feature of the oygenation container is to pump oxygen right into the storage tank to encourage the break down of any kind of organic product (and the development of the microorganisms), in addition to guarantee there suffices time for the organic product to be damaged down.

Uv Filtration Things To Know Before You Get This

This procedure is managed to provide the ideal conditions for bacterial development. Oxygen gas [O2] levels below 2 ppm will certainly exterminate the germs, reducing effectiveness of the plant. Liquified oxygen monitoring at this phase of the plant is crucial. Ammonia as well as nitrate measurements are typical to gauge how effective the bacteria are in converting NH3 to N2.

Stage Five Additional Clarifier Dealt with wastewater is pumped right into a second clarifier to permit any remaining natural sediment to resolve out of treated water flow. As the influent departures the aeration procedure, it flows into an additional clarifier where, like the primary clarifier, any learn the facts here now really tiny solids (or penalties) sink to the base of the storage tank.

With the enhanced concentration of bacteria as part of the oygenation phase, there is a demand to check the outward bound effluent for microorganisms visibility or lack as well as to sanitize the water. This ensures that more than specified concentrations of microorganisms are not released right into the setting. Chlorination is the most typical and also cost-effective sort of disinfection however ozone as well as UV disinfection are also increasing in popularity.

10 Easy Facts About Uv Filtration Explained

Water is directed from the Head Container to the Claricone clarifier. Water goes into the clarifier at the blending area located in all-time low of the Claricone - uv filtration. Lime is included to the water in this area where it responds with the calcium and also the magnesium in the water to form speeds up.

After adequate time, fragments abide by each various other and expand right into larger fragments, or, floc, which is susceptible to settle in water. This procedure of floc formation is called flocculation. To aid in the flocculation of fragments, an anionic polymer is added in the blending zone of the cone. Information of water is accomplished by the seperation of suspended solids from water by gravity.

The clarified water actions upwards gradually, ultimately overlooking the effluent weir to the cone electrical outlet as well as on the to filters for more therapy. The click this link water plant includes a single phase lime softening operation to eliminate firmness. Hardness is brought on by the presence of liquified bivalent and also polyvalent metal ions, predominantly calcium and magnesium.

This is added both in the clearwell as well as the high solution discharge as water gets in the circulation system. Hydrofluosilicic acid provides the source of fluoride, which is helpful in the avoidance of dental cavity in children. A fluoride concentration of 1. 1-1. 2 mg/l is typically desirable in the plant tap.